Do you have a question?

If it is about control panels, we have the answer.

- Site Heusden-Zolder (HQ)

- Industrieweg 10,

B-3550 Heusden-Zolder - +32 (0)13 61 11 00

- info@pnvpanels.be

To the rhythm of the waves

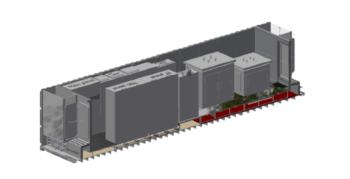

Everything involved in offshore wind farms is mega. To build such mega projects you also need even bigger ships. Meet the Orion from DEME. An offshore-installation ship that even manages to make a big impression in a sector where gigantic is the norm. On board, there are two containers with our panels for the deck supplies.

At 216.5 m long and 49 m wide, the Orion has an extraordinary transport and loading capacity. The deck provides space to store even the largest monopiles, jackets and wind turbine components in one piece.

Yet the deck provides more than just space. The Orion is a mobile site on which contractors complete the final tasks to get the components ready for installation. “This requires electricity”, begins account manager Nick Carmans. “DEME’s request was to engineer and build two containers to provide the power for what they refer to as the deck supplies. Going from a grinding wheel to a site hut, and everything a contractor may require.”

Project manager Alejandro Jimenez: “To be more specific: DEME required different 50 and 60-hertz socket outlets. Where contractors could get plugged in.” Why two different frequencies? “Because they wanted to be able to use their ship anywhere in the world. By using these two frequencies they covered everything. It was up to us to deliver these containers all ready to roll. So that DEME could simply lift them aboard, connect them up and use them right away.”

Different types of expertise, a single point of contact

“This project combines a range of experts. While DEME naturally only wants one point of contact. They already have enough other parties to align.”

“This is where the strength of our partner and supplier network comes in”, explains Nick. “It is up to us, as the main contractor, to know who can support us with which part of the puzzle. And up to us to coordinate everything and keep an eye on the deadlines. After all, the engineering and construction of the electrical panels is only one piece in the whole puzzle. We are also responsible for selecting the most appropriate transformers. The layout of the entire electrical set-up. The paint specs for the containers. Right down to the smallest details, such as the light fittings.”

“There are so many aspects to be taken into consideration”, adds Alejandro. “The cooling, for example. After all, a transformer emits a lot of heat. The fact that we have to place everything in the container on shock absorbers in order to cope with the waves. How and where to lay all the cables – as, in total, these add up to several kilometres. How to install everything as efficiently as possible in small spaces. This is when all our experience from similar projects in the past comes in really handy.”

Flagship

The Orion is the flagship in the fleet belonging to GeoSea, as DEME’s subsidiary. DEME is a specialist in dredging, land reclamation, port infrastructure, offshore services

for the oil and gas industry, and wind energy. The Orion is employed in building and dismantling large offshore wind farms..

The Orion in numbers

- 216.5 metres long. That’s the equivalent of two football fields.

- Loading capacity of 30,000 tons. Or the equivalent of 3,000 full lorries.

- A crane with a lifting capacity of 5,000 tons. That’s the equivalent of 5,000 cars.

- Installed capacity of 44,180 kW.

Engineering and construction of two containers.

Per container:

1x 1000kVA transfo

- 2100x1800x1200 (HxBxD) mm

- 2600 kg incl. casing

1x 630kVA transfo

- 1800x1200x1500 (HxBxD) mm

- 1900 kg incl. casing

- 10x socket outlets 50/60 hertz

- 5x 400A/4p

- 5x 250A/3p

3x power control centers from Logstrup

- 1600A, 800A and 630A

- 2500 kg in total (3 panels per container)

- 5 metres of panel in total (3 panels per container)

Airco

- 2x outdoor units with a cooling capacity of 22.5kW

- 2x downflow indoor units with a cooling capacity of 22.5 kW

1x control panel