Do you have a question?

If it is about control panels, we have the answer.

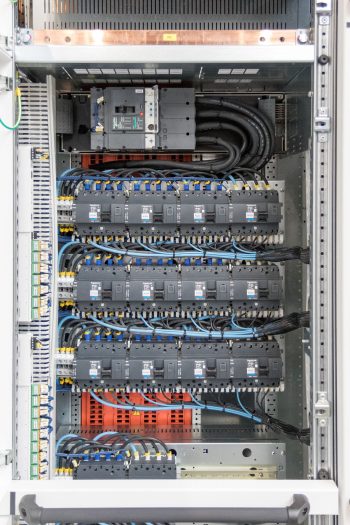

Main distributors at offshore sub-station

A wind farm the size of the town of Ranst. Or if you know the other side of Belgium better: comparable to the surface area of Merelbeke. That is the offshore wind park Hohe See. “And our first offshore project ever will be on this very mega project site”, says business development manager Roberto Musolino.

The park is located in the German North Sea, around ninety kilometres north of the island of Borkum. The project covers around forty square kilometres, and with 497 MW, is the largest planned offshore wind park in Germany. It is owned by EnBW: Energie Baden-Württemberg AG, the third largest energy company in Germany.

“A mega project involving a large number of different contractors. Engie is the Engineering, procurement and construction contractor. They regulate and coordinate everything and offer EnBW a turnkey solution. They are the contact point for the dredging activities over the metalworks all the way to electricity and finishing.”

“Our contribution: design and produce low-voltage panels for the module. In concrete terms, this means that distribution, mains low-voltage, patch and programmable logic controller panels. Thus it had nothing to do with the wind energy itself, but with the power distribution on the module.”

“And it was that very mega worksite that could become our very first offshore project. An incredible opportunity. But we first had to win that order. That was not an easy thing: it is a high-technology subject in a domain in which we had no experience. Offshore projects impose very specific requirements, for example, corrosion- specific requirements. And as if that challenge was not big enough, several specifications also had to be reconciled with each other.”

Thinking along and continuing

“Then we started to thoroughly investigate everything. Paragraph by paragraph. Once that was finished We went on to the next thing! Was something not clear? Check it through. By that time we had gone quite deep into the matter. This project required a huge amount of thinking, consultation with the customer and hours of preparation. We participated with Engie in the thinking process in order to obtain the best possible proposal.”

“Actually, we almost had to engineer the whole thing in the tendering phase itself. That however translated into a very detailed offer of 35 pages. And that without the technical drawings and the lay-out of the panels. In the meanwhile, we also started a process to obtain our Global Wind Organisation (GWO) certificate. We required that in order to execute site and harbour acceptance tests on offshore projects. In short: quite a lot of effort. Then it feels really good when you hear that you are selected.”