Do you have a question?

If it is about control panels, we have the answer.

Drawer per drawer to a smart MCC

Revamp only possible at a panel level? You’re wrong! Energy monitoring only something for new electrical panels? Wrong again. Just look at the revamp we achieved at Chevron Phillips Chemical.

Chevron Phillips Chemical is a global player in the production of ethene and polyethene. They supply products such as the raw materials for the type of lubricant used to keep machines and motors turning. It was our task to keep the production process at their site in Beringen up and running. Indeed, this was where the components in their motor control centre (MCC) were outdated. This meant that their electrical panels jeopardized operational reliability.

“In this kind of situation the first question is always: should we engineer and build new panels or renovate existing ones? Given the fact that we do both, we could develop a proposal for the two scenarios”, explains manager service Stijn Cuppens. “We weigh up the pros and cons, compare the budgets, define a schedule, etc. In this way we offer the customer all the information required to make the appropriate choice.”

It turned out that revamping was the best option for Chevron Phillips Chemical. A drawer revamp. “It is a misconception to think that we need to do everything in one go when we do a revamp. Compare it to a house. Either you go for a full renovation. Or you tackle things room by room. In the case of the latter the renovation takes longer, but you can phase the renovation and spread the cost.”

“By revamping each drawer individually, Chevron Phillips Chemical was able to spread their investment and the work over time. Another advantage was that there was no need for an additional and lengthy shutdown. We scheduled the work to fit in with the planned shutdowns.”

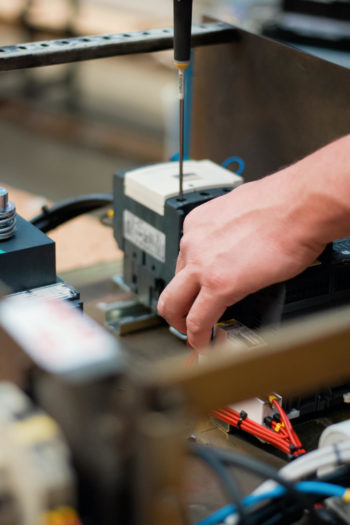

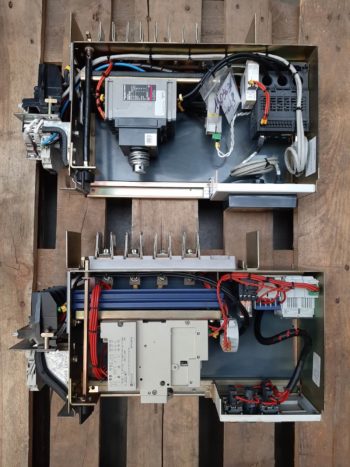

“Chevron Phillips Chemical has ten spare drawers. This means we can bring the same number back to our workshop in each phase. Here we replace the outdated components and bring everything up to the modern standard. We make every effort to ensure that the drawers are 99% plug-and-play.”

“Once everything’s in working order, we visit the site during a scheduled shutdown to reinstall the drawers. We also carry out the final adaptations on site: reinstalling, fine-tuning and restarting the production process. We then move on to the next batch of drawers. The end result is an MCC that can carry on for many more years.”

Revamp plus smart integration

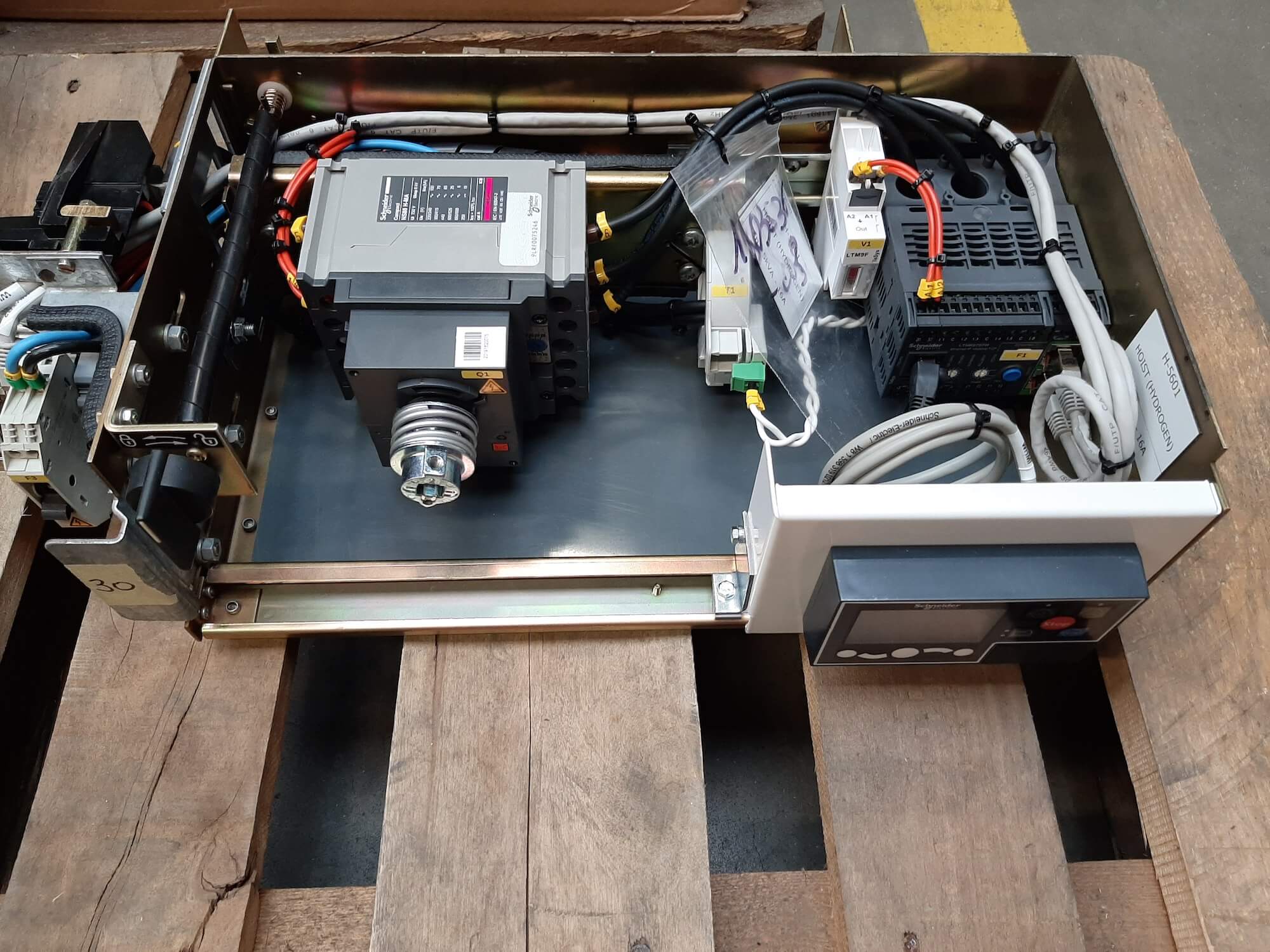

Task one was to bring the panels up to the modern standard. Task two: to make the MCC smart, in order to facilitate energy monitoring. “Most people think you need a new panel to have a smart panel. In fact, nothing could be further from the truth. We can also integrate smart aspects on existing panels”, says Stijn Cuppens. “In doing so, Chevron Phillips Chemical now has a perfect overview of the energy consumption on its different lines, as well as the ability to track such energy consumption from a distance.”

Turning 105 drawers into smart MCCs with a revamp.

- In different phases over a two-year period.

- Integrating smart components: Tesys T with Ethernet comm. and HMI.