Do you have a question?

If it is about control panels, we have the answer.

Upgrade of water purification control panels

Ever heard of effluent? It’s cleaned waste water. The cleaning process takes place at a water purification plant and involves several steps. One of those phases is to blow extra oxygen into the water. We carried out an upgrade one the control panels at the water purification plant in Houthalen.

It looks like a grid of bubbles on the water surface, as if, a few seconds ago, dozens of squares sank and left a trail behind. The real explanation is huge compressors that blow extra air into the basin through a pipe installation. This causes overpressure. The compressors and associated piping at the Houthalen water purification plant needed replacing. But if you replace the hardware, the control panels must also be replaced. This is because the new compressors require much less power than their thirty-year-old predecessors.

UPGRADE OF CONTROL PANELS

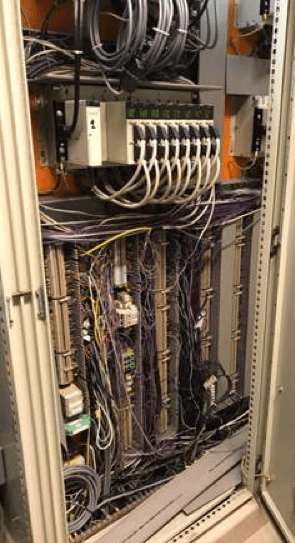

Replacing the current electrical installation was certainly an option, but Aquafin opted for an upgrade of the control panels. We took full responsibility for the job, although that was not the intention at first, explains Johan. “Their main contractor, VSE, a specialist in electromechanics in infrastructure works, asked if we would be able to update the schematic diagrams based on a set of specifications drawn up by Aquafin. The project grew continuously from one meeting to the next. We ended up on site for two months: dismantling, upgrading and rebuilding control panels, updating measuring and control boards, renewing old cabling, adding new ones, etc.”

“A serious job,” says Johan, looking back. “The old plans were not always clear, so we were constantly encountering unforeseen circumstances. What is the output of this cabinet? Why is this cable here and what does it do? We were looking for solutions to ever-appearing problems.”

RACE AGAINST THE CLOCK

And we had to do all of this to a strict time schedule because Aquafin had tight deadlines. Houthalen is one of the four sludge drying plants in Belgium, a specialty within the water treatment sector. “Every day that Houthalen did not reach maximum capacity, the other stations had to offset the pressure. The installation had to run continuously as a result. This is why we worked in different phases in upgrading the control panels for the water purification system in keeping with different deadlines within the overall project. This resulted in us having to work long hard hours – in shifts, overtime and weekends. Our technicians gave their utmost to meet all expectations. To top it all off, we experienced horrendous weather – it was either raining or freezing.”

“The end result is impressive,” concludes Johan. “They now have control panels that will last for years and plans that are completely up to date.”